Constructing devices

Since 2021, we have specialized in the production of assembly devices and stations for various industries. We solve technological problems in production processes by modernizing production lines and constructing devices tailored to customer expectations. These are devices that we make to special order

Assembly stations

Assembly stations are specially designed for the production of elements or assembly activities. The station may take the form of a stationary workplace, an assembly table or a specially created device. The assembly stations we design improve production efficiency and allow the employee to effectively perform assembly work.

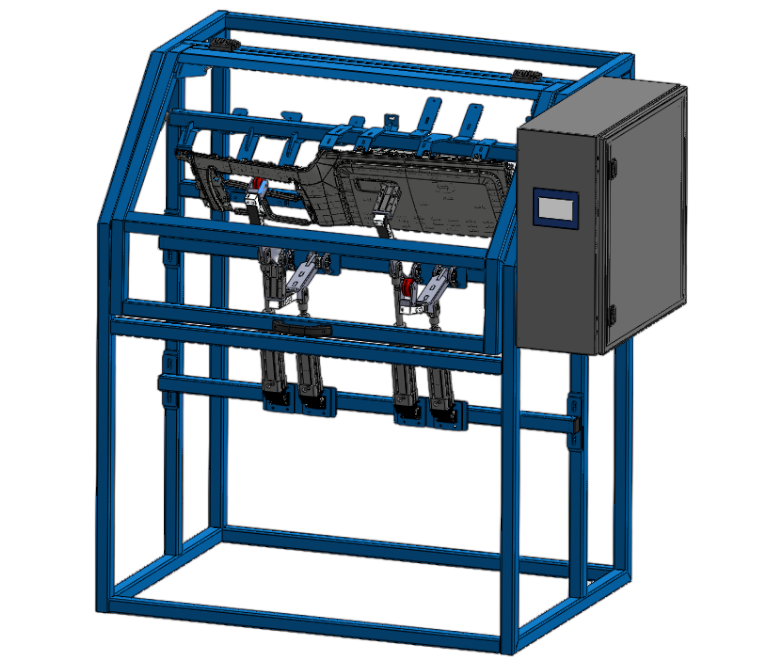

Assembly devices

Devices used to optimize production processes used in many industries.

We deal with assembly devices from the reported problem at the customer’s through concept, design, to production and implementation on the production line. We have a specialized machine park thanks to which weare able to make assembly devices entirely in our production place.

Testing devices

Testing devices are used to assess the efficiency, durability, safety and compliance with technical standards of various car components. They detect and eliminate errors in the operation of individual parts, which allows to ensure the required quality and prevent product defects. Our team will design fully automated testing devices

and implement the most optimal solutions for the benefit of the customer.

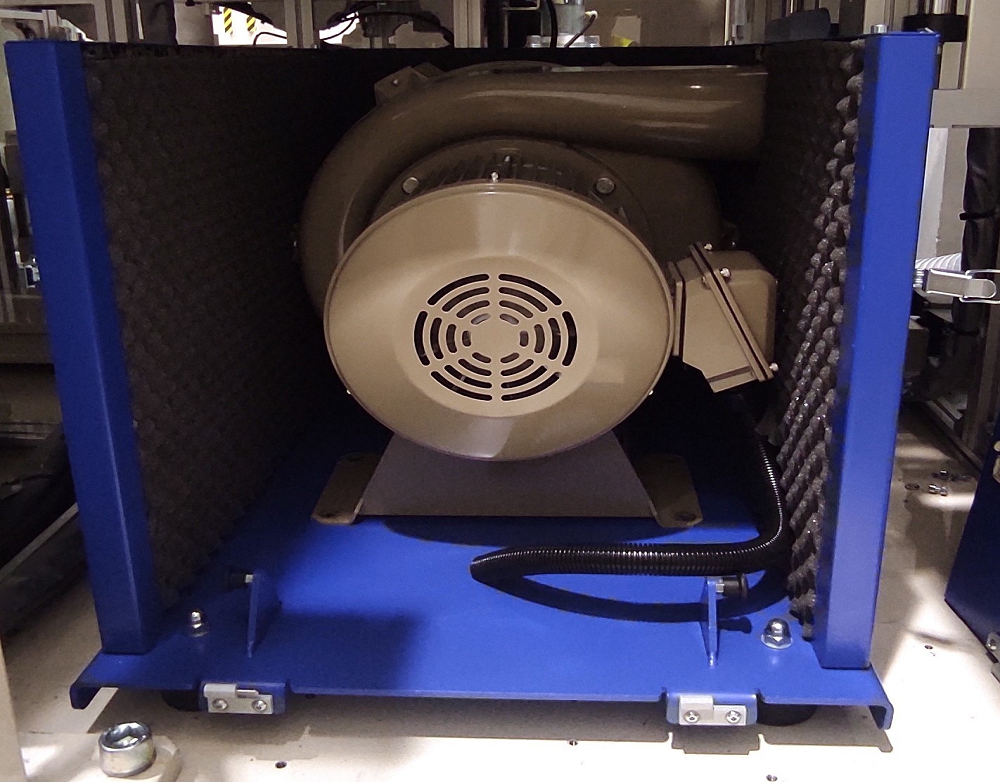

Designing enclosures

Acoustic enclosures reduce noise in an industrial environment by covering and muffling the source of sound emitted outside the enclosure. The production process consists of designing a sound-absorbing enclosure, then selecting acoustic materials, e.g. foam or fabric. The implementation process ends with the production of the

enclosure in accordance with the agreed technical documentation

Examples of device implementations

- Press – was made for a client from the automotive industry to make precise holes of specific shape and size in plastic parts.

- JIG – devices made for the customer to eliminate deformations and stresses in car parts through the process of cooling the parts in the mold, giving them the required shape and dimensions.

- Engine casing – made to order for a leading automotive customer, used to soundproof the engine on the production line.

- Glove compartment tester – the device is used to test car glove compartment. The tester creates controlled conditions that allow for precise testing of the parts’ operation within the given parameters (i.e. force, resistance) and identification of potential problems.